- sales@pacificsensortech.com.au

- Mon - Fri: 9:00 - 17:00

Menu

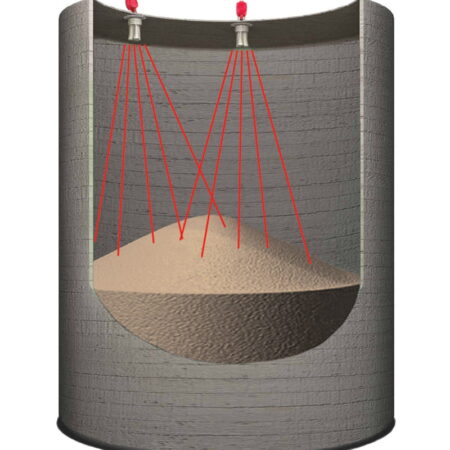

A 3DLevelScanner provides continuous, non‐contact level measurement using dust‐penetrating technology to provide very precise bin volume accuracy. It measures and maps the material surface to detect irregular material surfaces, cone up/down conditions, or sidewall buildup. A 3D scanner is unique because it can map the topography of the bin and create a computerized profile of its contents. Advanced acoustics‐based technology is proven to perform in high‐dust environments where some other types of non‐contact technologies struggle to perform reliably. A scanner can be used in bins as well as domes, warehouses, open bins, and piles.

A 3D scanner is ideal for bins with multiple filling and emptying points where the topography of the material is highly irregular. A 3D scanner can deliver one to three percent total stored volume accuracy when mounted in the proper location and used in a tank that is less than 45 ft. in diameter. For tanks greater than 45 ft. in diameter, a multiple scanner system can record measurement data from multiple devices and then combine the data to report volume to a personal computer and provide a single graphical representation of the tank contents.

Scanners come equipped with software that displays the bin data in an easy‐to‐read format. The measurements are sent to a main display screen and includes data such as average, minimum, and maximum distances; level; temperature inside the tank; and volume percentage. For operations with multiple bins, there is MultiVision software that allows for all bins to be monitored simultaneously from a single screen.

3D Level Scanner, Multiple point level measurement

...

3DLevelScanner for High Temperatures, has an operating temperature range up to 356°F (180°C). View Product

3D Multiple-Scanner System, integrates multiple-point measurement data from two or more 3DLevelSc...